Where should valves be positioned?

Guidance on the positioning of isolating valve

Updated Guidance: Double Check Valve/Non-Return Valve

Working with our fellow UK leaders in Waste Water Heat Recovery for Showers (WWHRS).

Together, we have reviewed the Water Supply (Water Fittings) Regulations 1999 along with the guidance available from Water Regs UK Ltd and have concluded that a Double walled WWHRS does not require a check valve to be fitted.

This installation guidance is in line with that of gas/electric boilers & instantaneous hot water heater (15 litres or under) with neither of these technologies requiring a check valve.

The water within the WWHRS once heated will not be drawn back into the cold water pipework and there is sufficient expansion room to accommodate any potential volume increase. This is a lower volume and temperature than a combi boiler or instantaneous water heater. Once the showering has finished, the pre warmed water held within the double walled WWHRS unit will cool back to mains temp quickly.

The requirement for installers and homeowners to protect the water undertakers mains supply into the property against backflow still remains.

Measures and double check valves should remain in place for single walled WWHRS units

Benefits to installers/developers

- Access panels not required

- • Double walled WWHRS do not require any additional backflow prevention

Updated Guidance: Concealed Isolation Valves

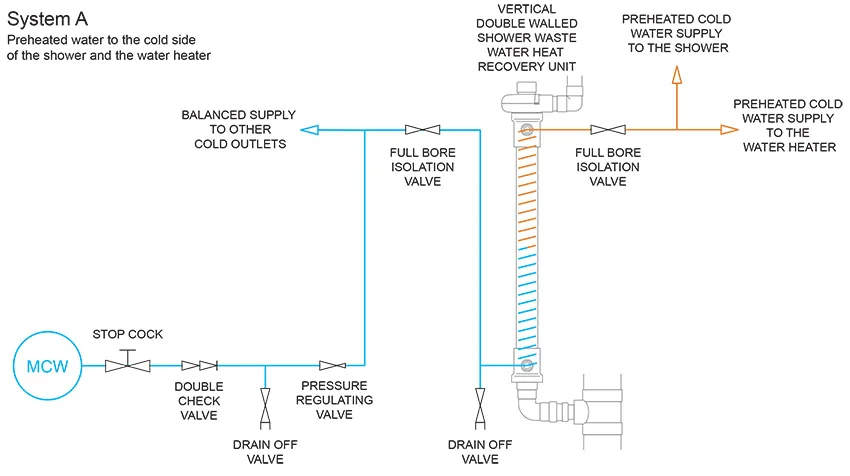

- Full-bore isolation valves are required to be installed with all types of WWHRS installations.

- Isolation valves should be installed to both the incoming CWM feed to the WWHRS and the out-flowing Preheated CWM feed from the WWHRS.

- Access to the valves is not required other than in the unlikely event the unit needs to be replaced. Best practice suggests that the valves should be placed in the same location that the unit is boxed in and must be made of corrosion resistant materials (such as CR brass).

- The homeowner document should reflect this position.

- Access Panels are not required.

Figure 1, A schematic drawing of a vertical WWHRS unit installed using System A installation method (Recoup)

Overview and background

Waste Water Heat Recovery Systems (WWHRS) for showers have been installed in the UK for 10+ years and the guidance offered by manufacturers has followed guidance that was available from WRAS in relation to the UK water regulations.

The WWHRS works on a completely passive basis, with no mechanical or electrical components or joints that require access for servicing or maintenance, with waste water passing through the system on one side of a heat exchanger and potable water passing on the other, effectively, a combination of waste pipe and water pipework.

Planned Maintenance:

There is no planned maintenance for the Double Walled WWHRS and they have a life expectancy in line with that of the plumbing pipework within the property.

Pressure Testing:

All Double Walled WWHRS should be pressure tested to the manufacturers requirements during installation to ensure connections are leak free before being concealed.

Current guidance from UK Water Regulations

UK Water Regs, Guidance: on the 23.07.2024.

Our collective interpretation of Paragraph 7 (3) is that with the use of isolation valves made of corrosion resistant materials (such as CR Brass), WWHRS installations can be concealed within SVP boxing, as we are also stating that the isolation valves are not operated for maintenance of the WWHRS unit and therefore not an ‘operational fitting’ after first fix and pressure testing of the complete system. Access to the valves is not required unless the WWHRS is to be removed, replaced or upgraded, at which point the isolation valves are accessible, so no access panels are required in the boxing.

This is supported by the ‘Guidance Paragraph 7’ (If behind plasterboard is not deemed accessible as it previously was) and would be similar to new build scenarios where valves for showers are behind plasterboard and tiles or under a bath that has been tiled in.

This guidance update is based on the following regulation from Water Regs UK Ltd based on Legislation:

- The Water Supply (Water Fittings) Regulations 1999 Paragraph 7

- The December 2023 document on the UK Water Regs website

- The previous guidance from WRAS (Now Water Regs UK) since WWHRS started to be installed in the UK (Specifying what finishes were and were not deemed as accessible)

For further information please contact us.

![Recoup Logo HR_50mm (RGB).jpg]](https://knowledge.recoup.co.uk/hs-fs/hubfs/Recoup%20Logo%20HR_50mm%20(RGB).jpg?height=50&name=Recoup%20Logo%20HR_50mm%20(RGB).jpg)